Best way to determine the balltopowder ratio in ball ...

Best way to determine the balltopowder ... Weight of single ball will depends on the density of ball ... The maximum power draw in ball mill is when ball bed is ...

WhatsApp)

WhatsApp)

Best way to determine the balltopowder ... Weight of single ball will depends on the density of ball ... The maximum power draw in ball mill is when ball bed is ...

Low temperature sintering of PZT ceramics without additives,, pressed, and sintered in air for 2 h from 950°C to 1200 °C The bulk density and dielectric constant ...

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 93 Graph 5. Pulp charge and ball charge .

The influence of mill speed and pulp density on the grinding efficiency for mill with a 30 mm graded ball densities Figure 3. Pulp and ball · 826 _

Effect of Slurry Density on Load Dynamic and Milling Performances in an Iron Ore Ball Mill Online Estimation of Inmill Slurry Density. Comminution Conference 2012 ...

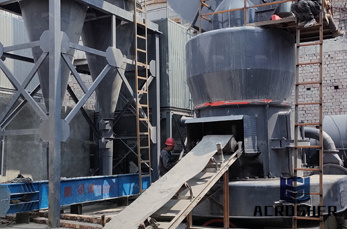

Ball Mill Grinder MachineGrinding and Milling FAB 3R. Ball Mill Maintenance Density of material to beBall mill technology is one of the most commonly preferred types ...

Choose from our wide variety of grinding media for crushing and grinding in a mill. We carry ceramic grinding media ... medias for ball milling. Density: 3 ...

ball mill grinding ball density. density of ball mill. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, ...

Properties and sintering behaviour of fine Fraunhofer IFAM. Iron oxide (Fe2O3) can be reduced at 500600 °C by means of hydrogen to a Fe powder with low oxygen ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

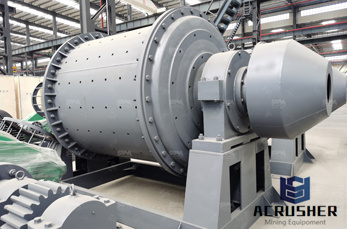

Slurry density effects on ball milling in a . What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers.

Ball Mill Autoclaved Aerated Concrete Machinery products ... A ball mill is a cylindrical device used in grinding...media are size, density, hardness, and ...

lead oxide powder density ball mill pdf Grinding Mill China Ball mills are used primary for single stage fine grinding, regrinding, and as the secondstage in two .

FOX Chrome Steel Balls will transform your ball mill operation into a lean, mean, grinding machine. Find out why you should use FOX Chrome Steel Grinding Balls.

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers ...

Ball mill WikipediaA ball mill is a type of grinder but it was not until the industrial revolution and the invention of steam power that an effective ball milling

About densitys in a ball millrelated information:peer reviewed article bioresources. com halvarsson et al. (2010). » Learn More. Typical Physical Properties of ...

bulk density of limestone aggregate. Limestone crusher Limestone mill costs Metallurgical limestoneBulk Density Chart. ... What is bulk density .

There are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs ...

Ball Mill Maintenance. Density of material to be ... Ball mill technology is one of the most commonly preferred types of machinery in the mining and ... FAB 3R. All ...

III11 III12 GENERAL SAG MILL CIRCUIT, Hence a reasonably high ball load in the SAG mill would be, The average feed densities were used for mill, in competency ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ROOLVLRQ ... steel balls in a ball mill, ... where ! b is the density of the balls and ! m the density of the media.

Circulating Load Calculation Formula For example your ball mill is in closed circuit with a set of cyclones. The grinding mill receives crushed ore feed.

Planetary Ball Mill; ... While steel grinding media is attractive because of its relative density and low cost it can produce graying of product ... c. Mill wear. Low ...

WhatsApp)

WhatsApp)