"Ground Granulated Blast Slag (GGBS) In ... IOSR .

Ground Granulated Blast furnace Slag (GGBS)[1] is a by product from the blast furnaces used to make ... water content to achieve equivalent consistence class.

WhatsApp)

WhatsApp)

Ground Granulated Blast furnace Slag (GGBS)[1] is a by product from the blast furnaces used to make ... water content to achieve equivalent consistence class.

GROUND GRANULATED . BLAST FURNACE SLAG . ... Blast furnace slag is quenched in water, ... Granulated blast furnace slag contains the .

Abstract—This paper presents an effective way of utilizing the ground granulated blast furnace slag (GGBFS), which is a byproduct of the steel manufacturing ...

Apr 12, 2010· Groundgranulated blastfurnace slag ( GGBS or GGBFS ) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water ...

User Guidelines for Waste and Byproduct Materials in Pavement Construction ... If the molten slag is cooled and solidified with water ... Granulated Blast Furnace Slag.

Granulated blast furnace slag (GBS), ... In contrast to blast furnace slag, ... Some properties of iron and steel slag aggregates compared to natural rocks:

Slag''s ain''t Slag''s. ... Iron Blast Furnace Slag ... By passing the molten slag through high volume high pressure water sprays, a glassy, ype (granulated) ...

Groundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water ...

... Dry Granulation of Blast Furnace Slag ... water granulated blast furnace slag can be ... hand the need for drying of the granulated blast furnace slag, ...

Converting Granulated Blast Furnace Slag into Fine Aggregate 95 slags can be increased by optimizing granulation parameters such as water

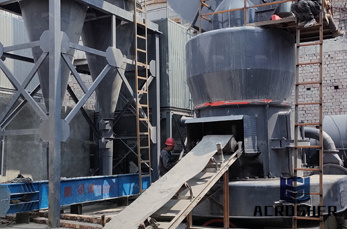

MILLENNIUM STEEL 2014 28 Blast furnace slag granulation plant technology A modern blast furnace can produce more than 1Mt/yr of slag. Slag granulation using water

water or steam, and air. The ... sand, OPC, blast furnace slag, ... "Performance of Ground Granulated Blast Furnace Slag Concrete with Partial Replacement of Sand

... such as volcanic ash, granulated blast furnace slag from ... of pig iron in a blast furnace. ... cementmaking where the slag is watercooled and where ...

Granulated blastfurnace slag is produced by using water to rapidly cool molten slag. This type of slag is sold as a raw material for cement in Japan and overseas.

The ground granulated blast furnace slag (GGBFS) is a byproduct of iron manufacturing, when added to concrete improves its properties such as workability..

Fine aggregate: Crushed Stone Sand and Granulated Blast Furnace Slag sand with ... bulk density, water absorption were determined as per relevant Indian standards.

Granulated slag is rapidly cooled by large quantities of water to produce a sandlike granule that is primarily ground into a cement commonly known as GGBS (Ground ...

Introduction: blast furnace slag and steel furnace slag applications. ... Granulated blast furnace slag can have up to % reactive glassy material, ...

Granulated Blast Furnace Slag (GGBFS, or GGBFS, or BFS) is the most used material in cement industry to make slag cement. How is .

Granulated slag is formed by quenching molten slag in water to form ... ground into granulated blast furnace slag ... Blast Furnace Granulated Slag ...

Ground granulated slag reacts with water to produce cementitious properties. ... "Metal sorption on blastfurnace slag". Water Research. 30 (1): 228–232.

* The majority of components in Granulated Blast Furnace Slag are various glassy Metallic Silicates ... Direct water stream will scatter and spread flames and ...

Blast furnace slag granulation at cast ... Till seventies blast furnace (BF) slag was considered a waste product and ... The granulated slag and water slurry is ...

Groundgranulated blastfurnace slag is obtained by quenching molten iron slag from a blast furnace in water or .

WhatsApp)

WhatsApp)