Advanced process control for the cement industry

Advanced process control for the cement industry ... reducing the feed and monitoring the mill until normal ... dynamics of the process. Compared to ball mills .

WhatsApp)

WhatsApp)

Advanced process control for the cement industry ... reducing the feed and monitoring the mill until normal ... dynamics of the process. Compared to ball mills .

dry feeding to ball mill. ... The dry process and the wet process. Ball mill can be divided into ... This ball mill is made up of feeding ...Get Price.

feed ball mill cement Crusher Machine vstorgin. feed ball mill cement, Ball mill, rotary dryer, Rotary kiln, Benficiation Line news Work Process of Ball Mill in ...

A ball mill is a type of grinder used to grind and blend Ball mills are used extensively in the mechanical alloying process Ball milling boasts ... feed mill flow ...

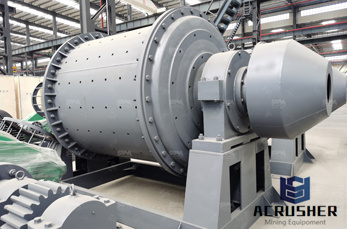

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building ...

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, M. Yang UNION PROCESS INC. Akron, Ohio Presented by Robert .

Grinding Classification Circuits ... Is there any other sideeffects associated with feeding a ball mill ... as well as trommels and feed chutes in the process.

Ball Milling Process zenith Heavy Industry. Structure of Ball Milling: The ball mill is composed of feeding part, the discharging part, turning part, transmission ...

The research topics is the ball mill to the mine control systems strategy study ... milling classification process, ... Ball mill feeding system to the grinding mine.

What is a ball mill? What are its uses and advantages ... shaft ball mill feed end into ... laboratory scale to process ceramic materials. Milling a ...

ball mill feed device for feeding of ball mill is a complete system, which has great influence on the ball mill output. The traditional feed form generally has three ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

ball mill feeding process. Ball Mills Mining Machinary REMAS. Key figures to determine the mill sizing are the ore charactheristics, the feed size.

Ball mill, an energysaving ... Ball mills are the key equipment for grinding after the crushing process, ... Ball load (t) Feeding size (mm) Discharging size (mm)

ball mill feed control using electric ear ball mill feed control using electric ear is one of our most main ... Grinding in Ball Mills: Modeling and Process Control.

A ball mill can grind and homogenize small sample volumes down to ... A ball mill for powerful size reduction and homogenization. ... Feed material: mediumhard ...

Feed Back. Patterson Industries Ball Pebble Mills. PATTERSON Industries Canada "The Process Equipment People" designs, engineers and manufactures Batch ...

gypsum feeding in ball mill design ... The crusher is designed to have a capacity ofwithdrawn from the silo will be fed to the ball mill for the cement grinding process.

There are efficiency factors for dry grinding, open circuit ball milling, mill diameter, oversize feed, the dry process ball mill and the wet process ball .

Ball mill feeding system to the grinding mineShanghai . Ball mill feeding system to the grinding mine. Milling process is the final stage smash, at this stage ...

Aug 18, 2017· Ball Mill Dry Process India. ... Feed Milling Processes ... The general process involves passing a feed . Chat Online; Planetary Ball Mill PM 100 ...

F 80 is the mill circuit feed size in micrometers. Rod mill ... and can be used after ball mills in a grinding process. Like ball mills, grinding ...

Grinding in Ball Mills: Modeling and Process Control ... and control of the grinding process in industrial ball mills. ... size required from a given feed size

Sep 06, 2017· Feed Back. Ball Mill Heavy Industry Crusher Mills, Cone . Brief introduction Ball mill is widely used in powdermaking production line of cement ...

WhatsApp)

WhatsApp)